JBS-C Series Impact Testing Machine

Product description:

1. Capacity: 150J,300J,450J,600J,750J 2. Application JBS-CComputerControlSemi-automaticCharpyImpactTestingMachineisusedformeasuring themetalmaterialresistanceperformanceunderdynamicload,inordertodeter1. Capacity:

150J,300J,450J,600J,750J

2. Application

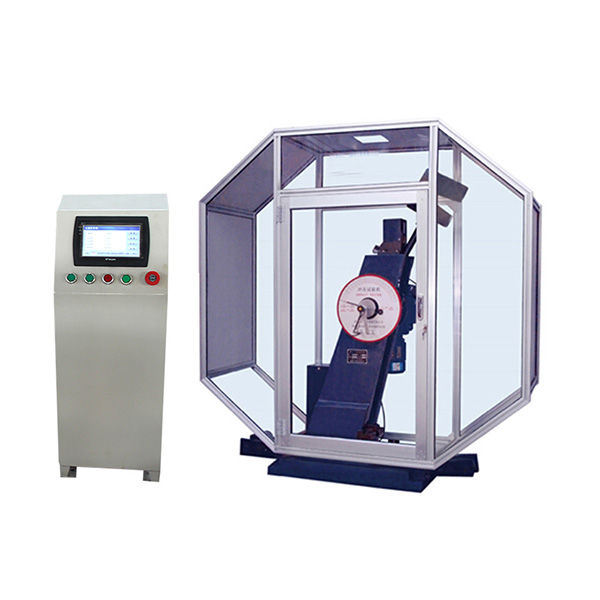

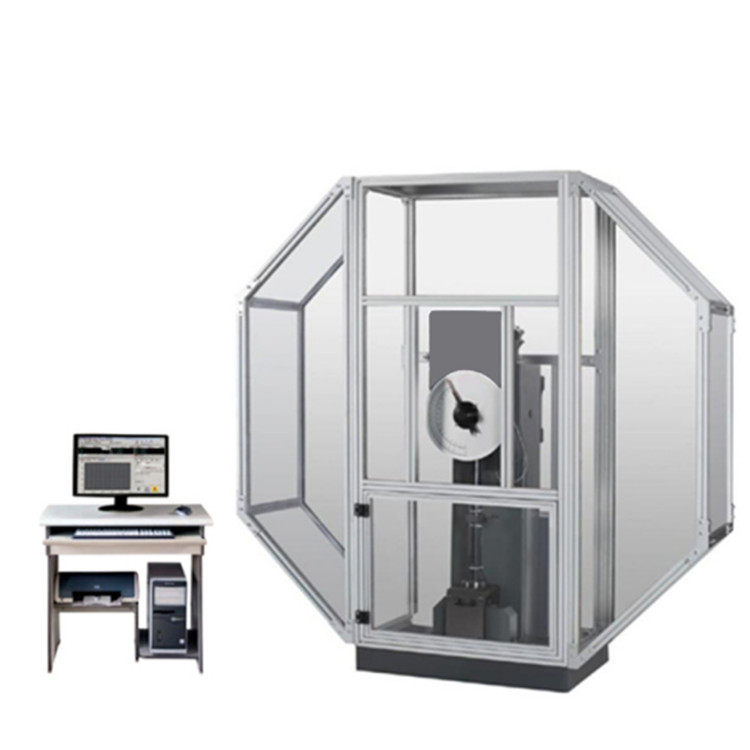

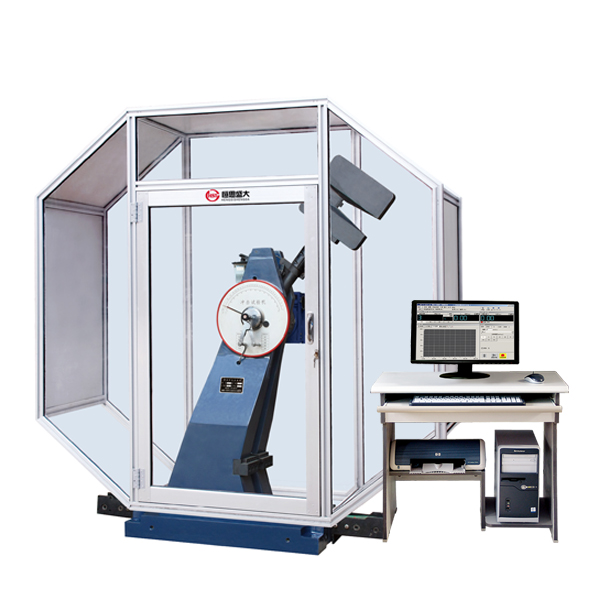

JBS-C Computer Control Semi-automatic Charpy Impact Testing Machine is used for measuring

the metal material resistance performance under dynamic load,in order to determine the material

properties under dynamic load.

It’s a necessary Testing machine,not only used in the metallurgy,machine manufacture etc areas,

but also used for the science research.

3. Standards:

ASTM E23, ISO148-2006 and GB/T3038-2002, GB/229-200,ISO 138,EN10045.

4. Main Technical Specifications:

5. Features:

5.1 One-body cast frame design of seat and column provide high stability.

5.2 Front and rear columns are symmetrical. Pendulum arm is designed of cantilever beam support, with simple structure and high machined precision.

5.3 Apply high precision bearing with small friction. Absorbing energy without loading is less than 0.3%.

5.4 Double reduction gear system replaces old style drive system with high efficiency and avoiding transmission failure.

5.5 High rigid pendulum arm prevents axial and transverse vibrations.

5.6 Exchangeable pendulum is simple to change to satisfy impact energy of 150J, 300J, 450J, 600J, 750J.

5.7 Electromagnetic release of pendulum hammer and electromagnetic clutch for locking the pendulum and raising it to its initial position. A damper is equipped to prevent strong bump when clutching.

5.8 Full-closed enclosure with high safety to prevent broken sample from splitting. Protective screening has interlock door. When the door opens, most operations can’t work to avoid any wrong operation.

5.9 Apply SIEMENS industrial PLC to control pendulum, The whole system is stable, reliable and accurate.

5.10 Big touch screen monitor may real-time displays striker angle, impact energy, toughness,and other parameters. User can input specimen data and other information such as company information into this monitor. When connected to a printer, user input information and test results will be printed(optional)

5.11 Optional cooling system is available to satisfy cold specimen test down to -180℃(optional)

150J,300J,450J,600J,750J

2. Application

JBS-C Computer Control Semi-automatic Charpy Impact Testing Machine is used for measuring

the metal material resistance performance under dynamic load,in order to determine the material

properties under dynamic load.

It’s a necessary Testing machine,not only used in the metallurgy,machine manufacture etc areas,

but also used for the science research.

3. Standards:

ASTM E23, ISO148-2006 and GB/T3038-2002, GB/229-200,ISO 138,EN10045.

4. Main Technical Specifications:

| Model | JBS-300C | JBS-450C | JBS-600C | JBS-750C |

| Max. impact energy(J) | 300 | 450 | 600 | 750 |

| Pendulum Torque | 160.7695 | 241.1543 | 321.5390 | 401.9238 |

|

The distance between the pendulum shaft and impact point |

750mm | |||

| Impact speed | 5.24 m/s | |||

| Raised angle | 150° | |||

| Round angle of the jaw | R1-1.5mm | |||

| Round angle of impact edge | R2-2.5mm,R8±0.05mm | |||

| Angle accuracy | 0.1° | |||

| Standard specimen dimension | 10mm×10(7.5/5)mm×55mm | |||

| Power supply | 3phs, 380V, 50Hz or specified by users | |||

| Net Weight (kg) | 900 | |||

5. Features:

5.1 One-body cast frame design of seat and column provide high stability.

5.2 Front and rear columns are symmetrical. Pendulum arm is designed of cantilever beam support, with simple structure and high machined precision.

5.3 Apply high precision bearing with small friction. Absorbing energy without loading is less than 0.3%.

5.4 Double reduction gear system replaces old style drive system with high efficiency and avoiding transmission failure.

5.5 High rigid pendulum arm prevents axial and transverse vibrations.

5.6 Exchangeable pendulum is simple to change to satisfy impact energy of 150J, 300J, 450J, 600J, 750J.

5.7 Electromagnetic release of pendulum hammer and electromagnetic clutch for locking the pendulum and raising it to its initial position. A damper is equipped to prevent strong bump when clutching.

5.8 Full-closed enclosure with high safety to prevent broken sample from splitting. Protective screening has interlock door. When the door opens, most operations can’t work to avoid any wrong operation.

5.9 Apply SIEMENS industrial PLC to control pendulum, The whole system is stable, reliable and accurate.

5.10 Big touch screen monitor may real-time displays striker angle, impact energy, toughness,and other parameters. User can input specimen data and other information such as company information into this monitor. When connected to a printer, user input information and test results will be printed(optional)

5.11 Optional cooling system is available to satisfy cold specimen test down to -180℃(optional)

Jinan Hensgrand Instrument Co., Ltd.

Jinan Hensgrand Instrument Co., Ltd. +86-15910081986

+86-15910081986  +86-15910081986

+86-15910081986

4915,West jingshi Road,jinan 250012,PR CHINA.

4915,West jingshi Road,jinan 250012,PR CHINA.