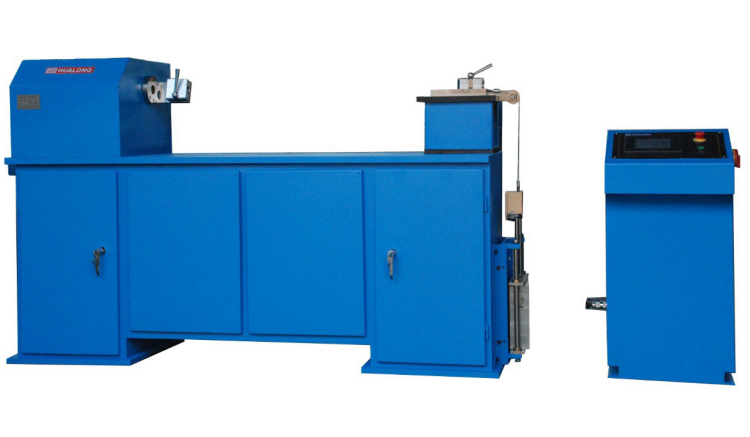

NDS Series Digital Display Material Torsion Testing Machine

Product description:

1. Application: This series materials torsion testing machine is used for torsion test of metal materials, nonmetallic materials, composite materials and components 2. Standard: GB/T 10128-1998 Meta t1. Application:

This series materials Torsion Testing Machine is used for torsion Test of metal materials, nonmetallic materials, composite materials and components

2. Standard:

GB/T 10128-1998 “Meta torsion test methods under room temperature”

GB/T 10128-2007 “Meta torsion test methods under room temperature”

3. Technical parameter:

4. Features:

1. Automatic stop:After the sample broke, the moving beam automatically stop 2.2. Display mode:During the test process, real time display the torque force, torque angle, torque speed, peak value, and test condition and others displayed in the same LCD screen;

3.Limit protection:with stored program control (SPC ) and mechanical two level limit protection

4.Overload protection: When more than 3 ~ 5% of the rated load device automatically stop working When the load over

5. Configuration

1. High strength torque Testing machine host(Table structure, spraying plastic processing machine-- 1pc

2. High precision angle encoder-- 1pc

3. High precision AC servo control system and AC servo speed regulating motor--1set

4. Taiwan ABBA precision linear guide--2 sets

5. High efficient needlework balance wheel reducer -- 1set

6. High precision torque sensor--1pc

7. Special torque grip--1 set

8. HST-N600 Torsion Testing machine special test and control system--1 set

This series materials Torsion Testing Machine is used for torsion Test of metal materials, nonmetallic materials, composite materials and components

2. Standard:

GB/T 10128-1998 “Meta torsion test methods under room temperature”

GB/T 10128-2007 “Meta torsion test methods under room temperature”

3. Technical parameter:

| Model | NDS-200 | NDS-500 |

NDS- 1000 |

NDS- 2000 |

NDS- 3000 |

NDS- 5000 |

| Max torque(N/m) | 200 | 500 | 1000 | 20000 | 3000 | 5000 |

| Test class | 1 class | |||||

| Control method | single chip control | |||||

| Torque test range(F·S) | 2%~100%F·S | |||||

| Torque value accuracy | ≤±1 | |||||

| Torque display resolution | 1/5000 | |||||

| Angle value accuracy (%) | ≤±1 | |||||

| Angle display resolution(°) | 0.01 | |||||

| Max torque angle | 99999° | |||||

| Torque angular rate control rang(°/min) | 0.05-800 | |||||

| Effective distance between chucks (mm) | 600 | |||||

| Test rotating direction | Two ways | |||||

| Power | 220V±10%,50Hz | |||||

4. Features:

1. Automatic stop:After the sample broke, the moving beam automatically stop 2.2. Display mode:During the test process, real time display the torque force, torque angle, torque speed, peak value, and test condition and others displayed in the same LCD screen;

3.Limit protection:with stored program control (SPC ) and mechanical two level limit protection

4.Overload protection: When more than 3 ~ 5% of the rated load device automatically stop working When the load over

5. Configuration

1. High strength torque Testing machine host(Table structure, spraying plastic processing machine-- 1pc

2. High precision angle encoder-- 1pc

3. High precision AC servo control system and AC servo speed regulating motor--1set

4. Taiwan ABBA precision linear guide--2 sets

5. High efficient needlework balance wheel reducer -- 1set

6. High precision torque sensor--1pc

7. Special torque grip--1 set

8. HST-N600 Torsion Testing machine special test and control system--1 set

Jinan Hensgrand Instrument Co., Ltd.

Jinan Hensgrand Instrument Co., Ltd. +86-15910081986

+86-15910081986  +86-15910081986

+86-15910081986

4915,West jingshi Road,jinan 250012,PR CHINA.

4915,West jingshi Road,jinan 250012,PR CHINA.