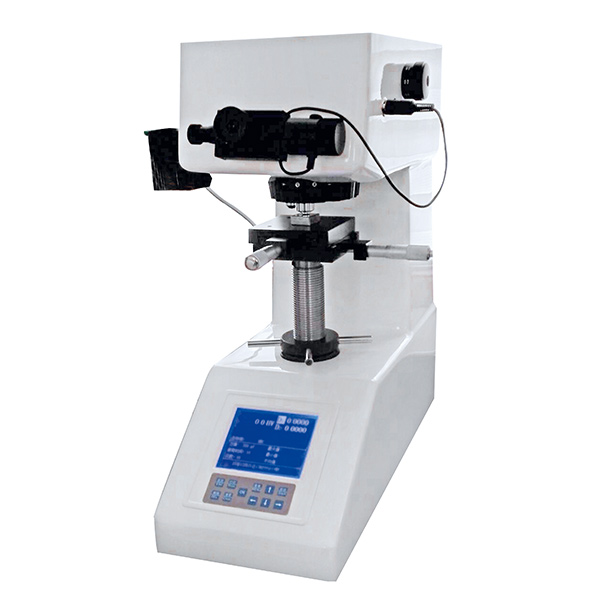

Micro hardness tester HV-1000Z with (Analog eyepiece, Auto-Turret)

Product description:

Main Function Features: 1. The optical system designed by our senior optical engineer not only meet the definition of hardness testing requirements, but also can observe the micro structure of the matMain Function & Features:

1. The optical system designed by our senior optical engineer not only meet the definition of Hardness Testing requirements, but also can observe the micro structure of the material, image is very clear.

2. According to different visual habits of the operators, the strength of the light source can be adjusted. To avoid the visual fatigue for long time operation.

3. With Vickers hardness and Knoop hardness Testing capabilities, and Testing force can be extended to 2KG (HV2). By measuring the indentation diagonal length, the hardness will show on the screen directly, no need to check hardness table.

4. One-time casting aluminum molding shell ensure structure more stable; Adopted car painting technology, pure white color looking more decent; High scratch resistance capability, used for years still brightness like new.

5. Factory directly supply, we have products develop &design & produce ability, all the parts provide life-time replacement and maintenance service.

Main purpose and application:

1. Steel, nonferrous metals, tinsel, cemented carbide, sheet metal, Metallographic structure.

2. Carburization, nitriding and decarburization layer, surface hardening layer, galvanized coating, coating.

3. Glass, chip and ceramic material.

Specification:

1. The optical system designed by our senior optical engineer not only meet the definition of Hardness Testing requirements, but also can observe the micro structure of the material, image is very clear.

2. According to different visual habits of the operators, the strength of the light source can be adjusted. To avoid the visual fatigue for long time operation.

3. With Vickers hardness and Knoop hardness Testing capabilities, and Testing force can be extended to 2KG (HV2). By measuring the indentation diagonal length, the hardness will show on the screen directly, no need to check hardness table.

4. One-time casting aluminum molding shell ensure structure more stable; Adopted car painting technology, pure white color looking more decent; High scratch resistance capability, used for years still brightness like new.

5. Factory directly supply, we have products develop &design & produce ability, all the parts provide life-time replacement and maintenance service.

Main purpose and application:

1. Steel, nonferrous metals, tinsel, cemented carbide, sheet metal, Metallographic structure.

2. Carburization, nitriding and decarburization layer, surface hardening layer, galvanized coating, coating.

3. Glass, chip and ceramic material.

Specification:

| Model | HV-1000Z |

| CE certificate No. : GB/1067/3980/12 Issue 1 | |

| Hardness conversion scale | HRA, HRB, HRC, HRD, HK, HBS, H15N, H30N, H45N, H15T, H30T, H45T |

| Test force | 10g (0.098N), 25g (0.245N), 50g (0.49N), 100g (0.98N ), 200g (1.96N), 300g (2.94N), 500g (4.9N), 1000g (9.8N) Test force error: ±1.0% |

| Loading speed | ≤50μm/sec |

| Indenter | Standard Rectangular pyramid diamond indenter (136º±0.5º) |

| Min. Measuring unit | 0.25μm |

| Hardness measuring range | 1HV-4000HV |

| Magnification | 400X(For Measurement) |

| Loading Method | Automatically(Load, dwell and unload) |

| Dwell time | 0-60s (each step is 1 second) |

| Tureet | Auto turret |

| Objective lens center and indenter center | Coincidence accuracy error < 1um (objective lens center position can be adjusted) |

| Max Height of Specimen | 200mm |

| Throat Depth | 80mm |

| Distance of Indenter to outer wall | 95mm |

| Instrument weight | 530mmX290mmX490mm 55kg |

| Light Source | LED Cold light source (can be continuous use for 24 hours, no heat generated, servicing life can reach 100,000 hours) |

| Power Supply | 220V + 5%, 50/60 Hz (110V is available) |

| X-Y Testing Table | Dim.:100×100 mm,Max. Travel Range: 25×25mm, Moving Resolution Ratio:0.01mm |

| Executed Standard | GB/T4340, ASTM E384 & E92, EN-ISO 6507, JIS B-7734 |

| Standard Accessories |

1 PIECE: 10X micrometer eyepiece ; 40X objective lens; Vickers indenter; Standard hardness block; X-Y Testing Table; Gradienter; Power cable; Dust cover; Manual Book; Hardness conversion tables; Quality certificate; Warranty card 4 PIECES: horizontal adjusting screw |

| Optional Purchase Accessories | Flat fixture; sheet specimen fixture, Small parts fixture, Image analysis software; Metallographic Equipment; Knoop Indenter; hardness block; 15X micrometer eyepiece |

Jinan Hensgrand Instrument Co., Ltd.

Jinan Hensgrand Instrument Co., Ltd. +86-15910081986

+86-15910081986  +86-15910081986

+86-15910081986

4915,West jingshi Road,jinan 250012,PR CHINA.

4915,West jingshi Road,jinan 250012,PR CHINA.