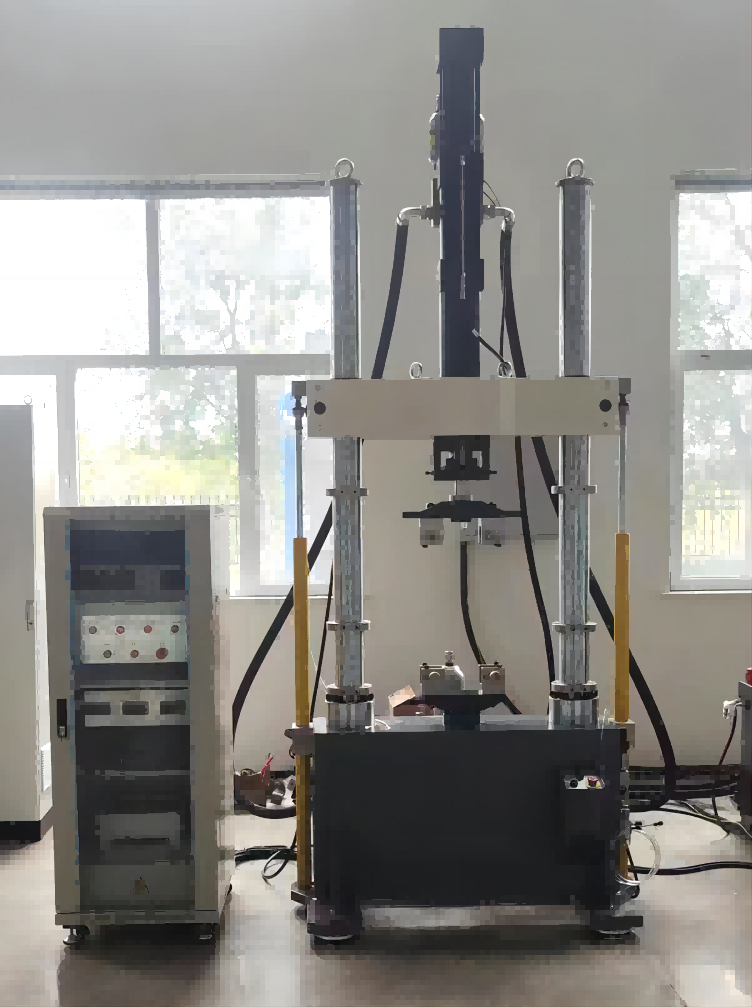

HST-P20JZ 0.2/s Servo Dynamic static fatigue testing system for shock absorber

Product description:

HST-P20JZ 0.2/s Servo Dynamic static fatigue testing system for shock absorber1. Application:

This equipment is suitable for static, dynamic, fatigue, creep and other Tests related to automotive rubber springs.

The system is equipped with special tooling for rubber components, with good versatility and advanced performance. It can also be used for low-cycle fatigue and high-cycle fatigue tests on various metal and non-metal materials. It can also conduct fatigue and static mechanical performance tests on various structural parts, components and assemblies.

If necessary, it can also be used for loading tests of other structural parts, components, and assemblies.

The system adopts electro-hydraulic servo technology and computer automatic control system operation. It has the characteristics of good professionalism, high reliability, advanced technology and wide range of use.

2. Standards:

Meet relevant standards such as QC/T491-1999 "Dimensional Series and Technical Conditions of Automotive Tubular Shock Absorbers" and QC/T545-1999 "Bench Test Methods for Automotive Tubular Shock Absorbers" to conduct shock absorber related tests, including: power test, speed characteristic test, internal friction resistance test, fatigue test, etc.

3. Technical Specifications:

|

Model |

Unit |

HST- P20JZ |

|

Force capacity |

kN |

±20 |

|

Vertical maximum test clear space

|

mm |

800 |

|

Actuator stroke |

mm |

±125mm (total stroke 250mm) |

|

Frequency range |

Hz |

0.01-30Hz |

|

Accuracy range |

% |

2%-100%FS |

|

Test force indication accuracy |

% |

±1.0 |

|

Fluctuation of dynamic indication of test force |

% |

±0.5 FS |

|

Main test waveforms |

- |

sine wave, sine wave, covector wave, triangle wave, square wave, pulse wave, ramp wave and custom programmable combination waveforms, etc. |

|

Maximum test speed |

m/s |

0.2 |

|

Test frequency (sine wave) |

Hz |

0.01~20Hz (Commonly used amplitude-frequency characteristics of loaded sine waves are shown in Table 1)

|

|

Servo pump station |

- |

45L/min, 21Mpa. Motor 22kW; |

|

Test space adjustment mode

|

|

Hydraulic lifting, hydraulic locking beam

|

|

Infrared temperature sensor |

℃ |

120 |

|

Protection function |

- |

low liquid level, over-temperature, oil filter clogging, overload, set test times reached, set parameters out of tolerance, specimen breakage, etc. |

Jinan Hensgrand Instrument Co., Ltd.

Jinan Hensgrand Instrument Co., Ltd. +86-15910081986

+86-15910081986  +86-15910081986

+86-15910081986

4915,West jingshi Road,jinan 250012,PR CHINA.

4915,West jingshi Road,jinan 250012,PR CHINA.