DPS-25B dynamic and static leaf spring fatigue testing machine

Product description:

DPS-25B dynamic and static leaf spring fatigue testing machine1. Introduction to series products

The DPS series electro-hydraulic servo dynamic and static fatigue Test bench is one of the series of dynamic fatigue loading test system products developed by our company. This series of products have the characteristics of wide output force range, high control precision, convenient use and high reliability. This series of test systems are designed by absorbing the international advanced electro-hydraulic servo dynamic Testing machine technology in the process of research and development, combining with the actual use of domestic users. Servo actuators, constant pressure servo oil source, loading frame and other key components are designed and manufactured by our company. The key outsourcing parts such as servo valves, sensors, seals are all selected international mainstream models, which greatly improves the stability and reliability of the system The overall performance of the Testing machine is equivalent to the international advanced product technology level.

The test system can not only perform dynamic high- and low-cycle fatigue tests, program-controlled fatigue tests, but also static tests under constant rate, constant strain, and constant stress control and various conventional mechanical performance tests. Safety evaluation of actual test pieces, simulation of working conditions, etc., by replacing Accessories, fatigue and static mechanical performance tests of various structural parts, components and assemblies can also be carried out;

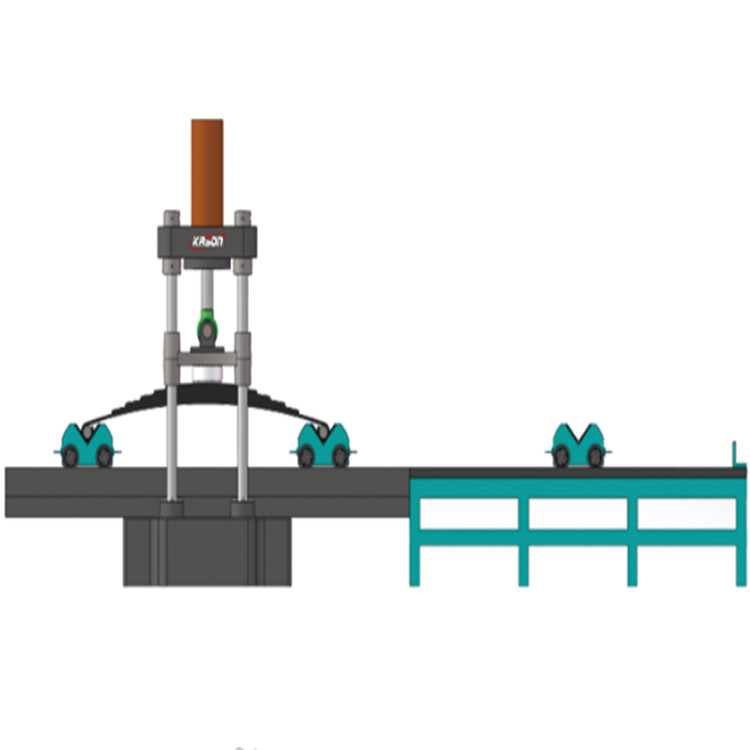

According to the characteristics of automobile leaf springs, this test bench has specially developed high-rigidity fixed gauge mainframe loading unit and hydraulic power unit, which can meet the detection and test of ear spring, no ear spring, one end with ear and the other without ear spring, so there are any other types The incomparable advantage of the testing machine is the most respected material testing equipment in the field of leaf spring fatigue mechanics.

Main unit parts of the test system:

Four-column double-guided high-rigidity host: 1 set; (actuator mounted on top)

21MP, 110L Siemens PLC intelligent control constant pressure silent servo pump station (oil source): 1 set; (including relay oil separator and relay energy storage system)

Special test software package for dynamic and static leaf spring fatigue: 1 set;

Standard version of measurement and control software package: 1 set

Imported measuring sensors (force, displacement): 1 set

Jinan Hensgrand Instrument Co., Ltd.

Jinan Hensgrand Instrument Co., Ltd. +86-15910081986

+86-15910081986  +86-15910081986

+86-15910081986

4915,West jingshi Road,jinan 250012,PR CHINA.

4915,West jingshi Road,jinan 250012,PR CHINA.