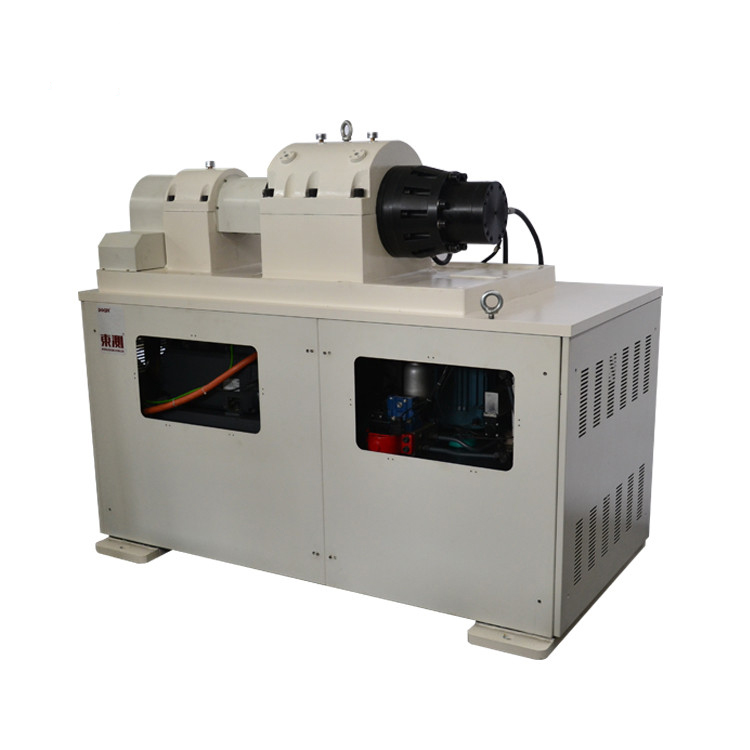

Hst-plw200 differential bearing two-channel dynamic simulation testing machine

Product description:

Hst-plw200 differential bearing two-channel dynamic simulation testing machinehe Testing machine is mainly used to simulate the actual working state of the differential bearing. Through bringing the radial bearing spectrum, the axial load spectrum, the rotational speed variation spectrum, the velocity spectrum and the load spectrum on Testing machine, Testing machine is used by programmed instruction to complete the durability test of the differential bearing.

Main specifications, technical parameters and technical indicators:

Main specifications, technical parameters and technical indicators:

| No. | Item | Main specifications, technical parameters and technical indicators |

| 1 | Test bearing inner diameter | Ф30-70mm,2 pieces per test |

| 2 | Maximum axial load of testing machine | ±100kN,steady-state error≤±2%FS |

| 3 | Maximum radial load of testing machine | ±200kN,steady-state error ≤±2%FS |

| 4 | Test bearing maximum speed | 5000r/min,steady-state error ≤±2%FS |

| 5 | Axial load, radial load and test speed can be loaded in a coordinated manner, and its coordinated phase can be set and controlled by computer. | |

Jinan Hensgrand Instrument Co., Ltd.

Jinan Hensgrand Instrument Co., Ltd. +86-15910081986

+86-15910081986  +86-15910081986

+86-15910081986

4915,West jingshi Road,jinan 250012,PR CHINA.

4915,West jingshi Road,jinan 250012,PR CHINA.