Electrohydraulic Servo Torsion Fatigue Tester

Product description:

Electrohydraulic Servo Torsion Fatigue TesterApplication:

Computer Control Electro-hydraulic Servo Fatigue Testing Machine is ainly used to detect a variety of metals, non-metallic materials and small movable member, the static mechanical properties Test. It can do tensile, compression, bending, low cycle and high cycle fatigue, crack growth, fracture mechanics test under sine, triangle, square wave, trapezoidal wave, random wave, combination waveform.

This Test machine is flexible, moving beam down, locking the sample holder by button operations, the use of advanced hydraulic servo drive technology loaded, high precision and high resolution dynamic load sensor magnetostrictive displacement sensor specimens force values and displacement.

Fully digital measurement and control system implementation force, displacement, deformation closed loop control, test software under WINDOWS Chinese working environment, powerful data processing capabilities, test conditions and test results are automatically saved, displayed and printed. Fully integrated into the computer-controlled test procedure, the Test machine is a research institutes, metallurgy building, defense industry, universities, machinery manufacturing, transportation and other industries ideal cost-effective test systems.

2. Standards:

GB / T2611-2007 《Tester General technical requirements》

GB / T16826-2008 《Hydraulic servo Universal Testing Machine》

GB 3075 《Axial fatigue testing metal》

JB / T9379-2002 《Tension and compression fatigue test machine technical conditions》

GB / T228-2010 《Metallic materials at room temperature tensile test method 》

4. Feature:

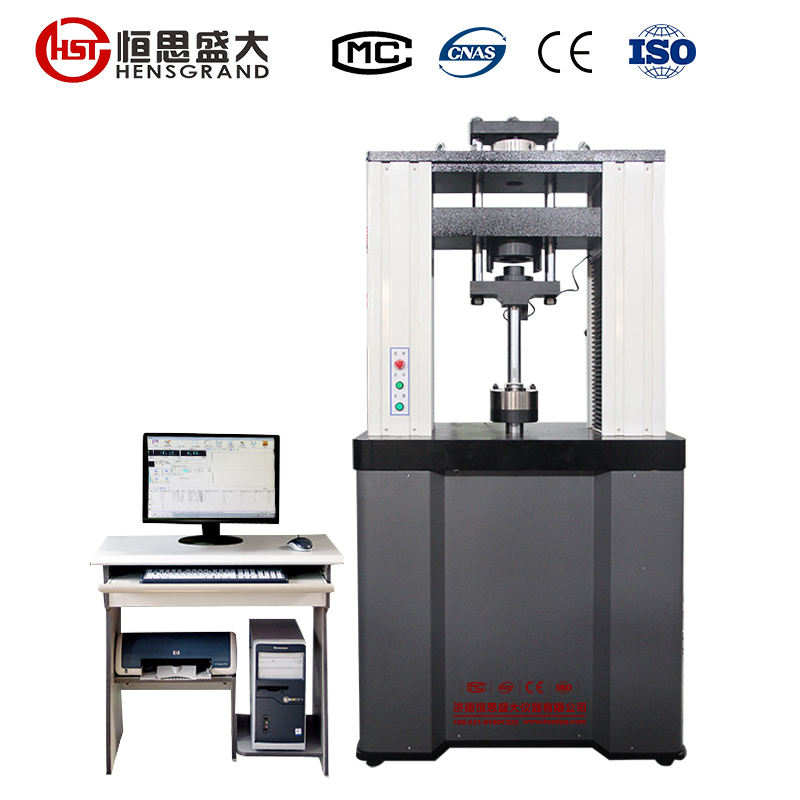

1. Test machine host: two columns, base, beams constitute enclosed frame structure, frame stiffness, no backlash, good stability. Two-column the outer surface of the hard chrome plating. Servo actuator (cylinder) at home, using double-acting cylinder piston design, convenient and flexible adjustment of the sample holder.

2. The key components: the use of international brands - American MOOG servo valve, HST-1000 controller, the United States World Civil sensors, Japan Fujikoshi pump, US company HST displacement sensors.

3. The hydraulic servo pump station: no leak quiet technology, stable pressure output, no volatility, low noise, good heat dissipation, high filtration precision, pressure overload, oil temperature automatic over-temperature protection.

4. Control: force, displacement, deformation PID loop control, and can achieve any control mode switching smoothly without disturbance.

Jinan Hensgrand Instrument Co., Ltd.

Jinan Hensgrand Instrument Co., Ltd. +86-15910081986

+86-15910081986  +86-15910081986

+86-15910081986

4915,West jingshi Road,jinan 250012,PR CHINA.

4915,West jingshi Road,jinan 250012,PR CHINA.