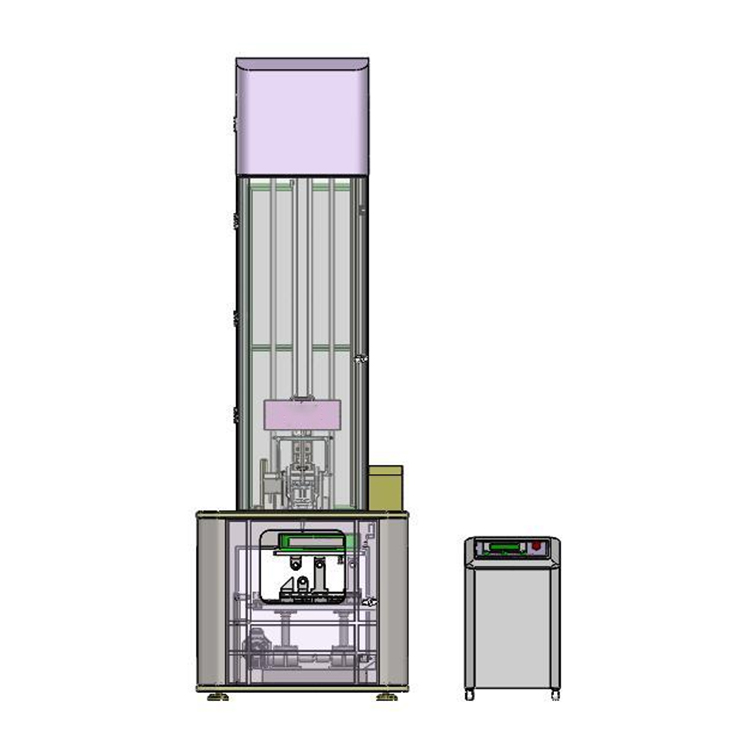

NDT Digital Display Drop Hammer Impact Test Equipment

Product description:

NDT Digital Display Drop Hammer Impact Test Equipment

NDT Digital Display Drop Hammer Impact Test Equipment

1. Application:

The drop hammer impact Test machine is mainly used for non-ferritic steels ductility transition temperature of the sample drop weight method, the test method is a certain quality of the hammer raised to a certain height, then there is static released, hammer body free fall impact to the sample surface, thereby determining the impact resistance of the sample. The drop hammer impact test machine integrating mechanical, electrical, automatic control technology, and to achieve a lifting hammer, feeding, shock, grab the hammer fully automated process. In addition to the Testing machine is equipped with multi-channel protection measures, greatly improving the safety of operating personnel and equipment use. This machine is applicable for nil ductility transition temperature Testing of ferrite steel.

2. Standards:

ASTM E208-2006,GB/T 6803-1986, API5L3,ASTM E436-80,

ASTM E604-83

3. Main Technical Specifications:

|

Model |

NDT -800 |

NDT -3000 |

NDT -4000 |

NDT-6000 |

|

Max impact energy(J) |

800 |

3000 |

4000 |

6000 |

|

Min impact energy(J) |

300 |

350 |

600 |

750 |

|

Hammer quality (Kg) |

70 |

70 |

80 |

80 |

|

Main hammer body quality error |

±1% |

|||

|

Impact height (mm) |

750mm~3200 |

|||

|

Impact speed (m/s) |

3.8-7.6 |

|||

|

Lifting hammer speed (m/min) |

7 |

|||

|

Height test resolution(mm) |

0.1 |

|||

|

Height test error(mm) |

≤±10 |

|||

|

Hammer blade hardness |

HRC≥50 |

|||

|

Hammer blade radius of curvature |

R25mm |

|||

|

Bearing hardness |

HRC58~62 |

|||

|

Hammer blade center、Sample center and Support center deviation (mm) |

≤±2.5 |

|||

|

Sample bearing span(mm) |

P-1:305 P-2、P-3:100 |

|||

|

Sample size(mm)(length×width×thickness) |

P-1 sample:(360±1)×(90±2)×(25±2.5) P-2 sample:(130±1)×(50±1)×(20±1) P-3 Sample:(130±1)×(50±1)×(16±0.5) |

|||

|

High Low temperature device |

-70℃ -- 150℃ |

|||

Jinan Hensgrand Instrument Co., Ltd.

Jinan Hensgrand Instrument Co., Ltd. +86-15910081986

+86-15910081986  +86-15910081986

+86-15910081986

4915,West jingshi Road,jinan 250012,PR CHINA.

4915,West jingshi Road,jinan 250012,PR CHINA.