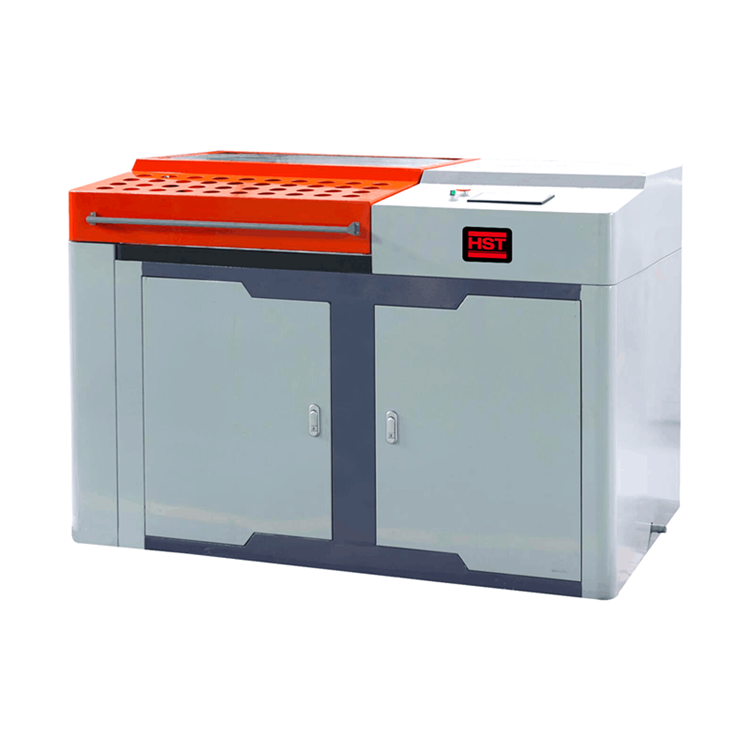

HST-BTG60 ISO 8491 Steel Pipe Bending Testing Machine

Product description:

HST-BTG60 ISO 8491 Steel Pipe Bending Testing MachineWelded (Low Pressure Fluid) Steel Pipe Bending Testing Machine" is a special equipment for plane bending Test of metal steel pipe.

Standard:

ISO 8491:1998 Metallic materials — Tube (in full section) — Bend test

ISO 5173:2023 Destructive tests on welds in metallic materials — Bend tests

ASTM AHST-22 Standard Test Methods and Definitions for Mechanical Testing of Steel Products

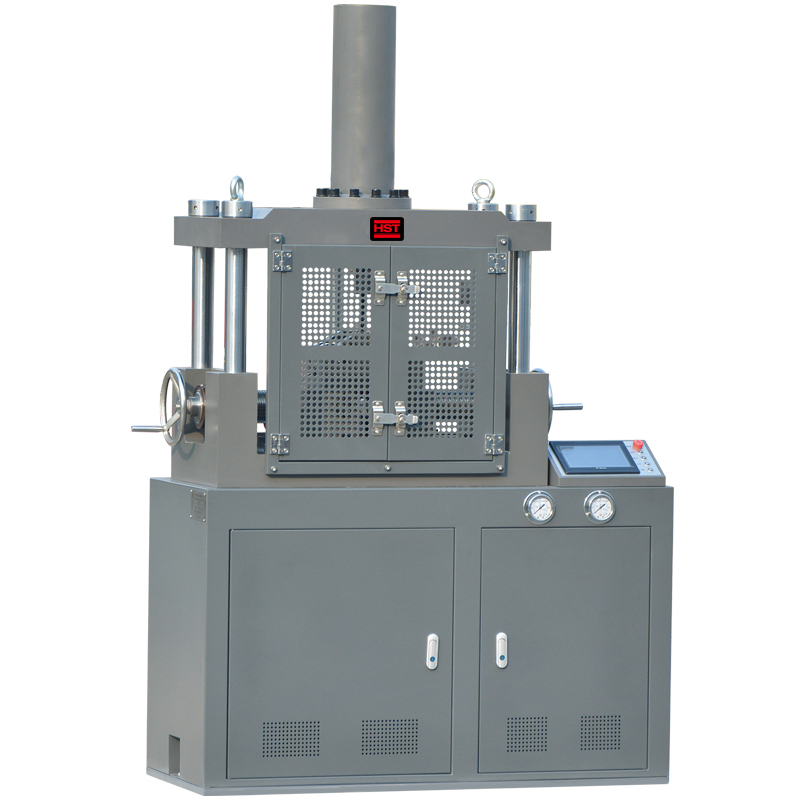

Main technical parameters:

|

Model |

GGW-60H |

|

Curved steel pipe nominal diameter range (DN) |

DN6(Φ10.2) ,DN8(Φ13.5) ,DN10(Φ17.2) ,DN15(Φ21.3), DN20(Φ26.9) , DN25(Φ33.7), DN32(Φ42.4), DN40(Φ48.3), DN50(Φ60.3) |

|

Steel pipe bending angle |

0°-90° free setting (Customized 0°-180° free setting available) |

|

Roller operating speed |

≤1.4 r/min |

|

Bending angle control accuracy |

±1.5° |

|

Equipped with bent sleeve radius R (6 times diameter) for steel pipe |

Φ21.3mm×6≈127.8mm;Φ26.9mm×6≈161.4mm;Φ33.7mm×6≈202.2mm Φ42.4mm×6≈254.4mm;Φ48.3mm×6≈289.8mm;Φ60.3mm×6≈361.8mm Optional: Φ10.2mm×6≈61.2mm;Φ13.5mm×6≈81mm; Φ17.2mm×6≈103.2mm; |

|

Wheel radius |

R5、R6.8、R8.6、R10.7、R13.5、R16.9、R21、R24.2、R30.2 |

|

Test control methods |

1. Manual control: the sample bending test is controlled manually, and the bending angle is controlled manually during the bending process; 2. Automatic control: the bending test is automatically controlled by the equipment, the bending angle can be set, the angle is displayed from time to time during the bending process, and it will automatically stop when the bending angle reaches the set angle. |

|

Motor power |

1.5kw |

|

Dimension |

970×760×1170mm |

Jinan Hensgrand Instrument Co., Ltd.

Jinan Hensgrand Instrument Co., Ltd. +86-15910081986

+86-15910081986  +86-15910081986

+86-15910081986

4915,West jingshi Road,jinan 250012,PR CHINA.

4915,West jingshi Road,jinan 250012,PR CHINA.